The refractory industry has certain requirements for three-dimensional mixers, and the requirements here are the micro-uniform mixing required by the refractory powder mixing industry, that is, micro-mixing.

Refractory materials are widely used in metallurgy, chemical industry, petroleum, machinery manufacturing, silicate, power and other industrial fields, the largest amount in the metallurgical industry, accounting for 50% to 60% of the total output. The refractory industry has certain regulations on the production process, especially the requirements of the refractory industry for the three-dimensional mixer in the mixing process are not only a single uniform mixing, but a comprehensive uniform, efficient and uniform micro-uniform mixing.

The important production process of refractory materials involves the powder mixing process used in the selection of three-dimensional mixer, which is the key process of this industry, and other processes to achieve the healthy and rapid development of the industry. Among them, there is the junction method of refractory materials, which is also the production process of refractory materials, sintering method is to preburn some raw materials, break and screen, and then mix with raw materials according to a certain ratio, after forming, drying and burning. The purpose of raw material pre-burning is to burn off the water, organic impurities, and gas decomposed by sulfate in order to reduce the burning shrinkage of the product and ensure the accuracy of the shape and size of the product. The raw material also needs to be screened after crushing and grinding, because the billet is graded by different particle sizes of powder, which can ensure the closest packing and obtain a dense billet. In order to homogenize the composition and particles of various raw materials and clinker, it is necessary to carry out mixing and add bonding agents at the same time to enhance the bonding strength of the billet.

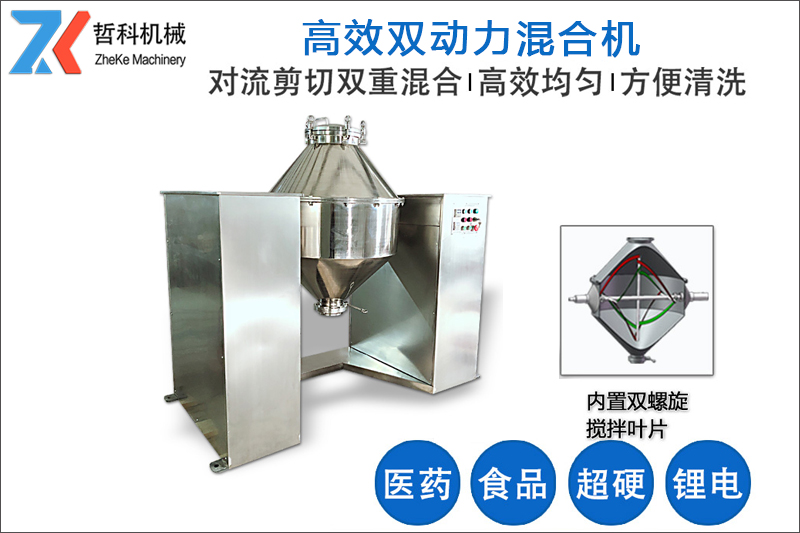

The good production of refractory materials is closely related to the efficient three-dimensional mixer. In the process of refractory mixed production process, clinker contains more than two of the raw materials, and raw materials are also containing a variety of raw materials. In order to improve product quality, homogenization between particles after mixing raw material and clinker is particularly important. Want to improve the homogenization of products, micro homogenization, here we need a device to help me achieve product homogenization, that is, dual power three-dimensional mixer.

How does the 3D mixer achieve the micro-mixing of refractory materials? Dual power three-dimensional mixer is widely used in the refractory industry, with advanced mixing process and mixing technology, and combined with the existing gravity diffusion mixer and forced shear mixer on the market at present, under the premise of ensuring the macro uniformity of products, but also to ensure the micro uniformity of products. For the refractory industry, it is a mixing expert, especially for some mixed difficult light and heavy powder, trace element additives have a good mixing effect.